Ferry Seats: Materials and Components Explained

Ferry seats are a crucial component of ship outfitting, made up of various parts such as seat skeleton, beams, legs, armrests, tracks, and more. When these parts are assembled together, they form the ferry seats that provide comfort and safety to passengers during sea travel.Choosing the right material for ferry seats is a vital consideration for ship owners, not only for class approval but also for long-term durability. Here’s a breakdown of the materials used in different parts of a ferry seat:

Seat skeleton

The seat skeleton is the main structure of a ferry seat. It must be made of aluminum tube. Firstly the aluminum tube is light weight compared with iron and steel tube. Secondly aluminum tube is much more durable than iron and steel tube due to its corrosion resistant in marine environment.

Beams,Legs,Tracks

The seat beams,legs, tracks are joint to a whole group. Tracks mounted on the floor. Legs stand on the track with a custom made screw inside. The seat beam fit on the two legs. The custom made screw joint the three parts as a whole. The seat fix on the beam with screws. This whole part is responsible for supporting the weight of passengers.

The beams, legs, and tracks of the ferry seats are made from aluminum profiles, with thickness sufficient to ensure their strength. Anodizing is used to treat the surface of the seat frames, serving three purposes. Firstly, it adds a decorative touch, making the seats look bright and shiny. Secondly, it enhances their resistance to corrosion. Lastly, it increases the hardness of the aluminum surface. Below is the assembly process for the seat frames.

Tracks also called rails. It is mounted on the deck floor with rivets or bolts. usually we need to weld a embedded part on the deck for fixing rivets or bolts. The tracks is 5 meters long , we can also cut it 2.5 meters for easy shipment.

The legs stand on the track with a custom made long bolts inside it.

The beam is fitted into the two legs properly.

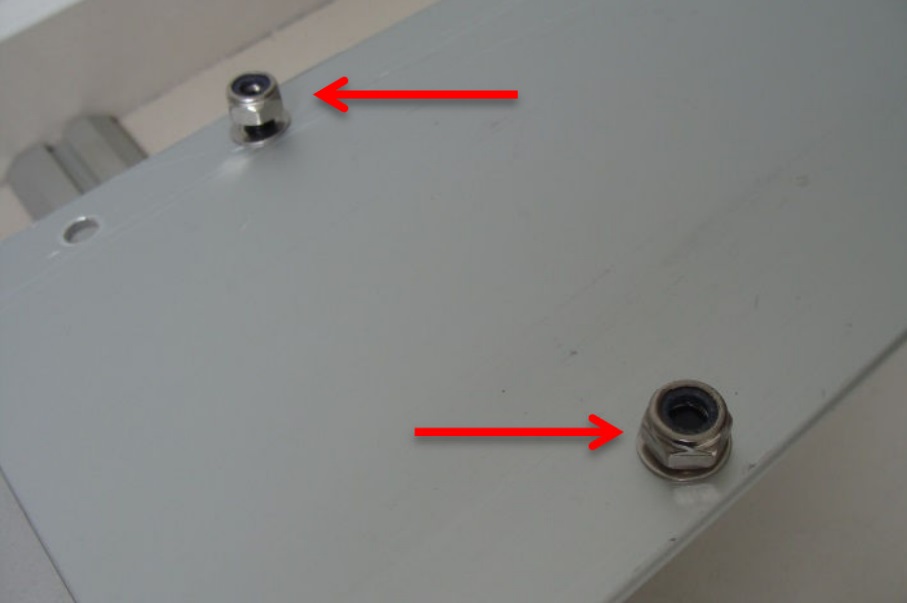

Fix the custom made long bolts with nuts.

Then , the seat frame is assembled.

Amrest

armrest is also made of aluminum profile. It looks like long aluminum strips but with rounded corner. The armrest can be made into various shapes. After the armrests were maded into a certain shape, the anodizing treatment must be processed to make the surface flawless and smooth. Armrest is installed on the beam and fixed with bolts.

Foam

The ferry seat cushion and backrest have two pieces of foam attached on the seat skeleton.The material of the foam is PU.It is produced by casting tooling to a certain shape.The foam must be high rebound to ensure the service life of the ferry seats.What’s more the foam must be fire retardant. The foam fire retardant testing should be conducted in IMO HSC certificate application for the ferry seats.

Upholstery

Upholstery can be fire retardant fabric, artificial leather , real leather.

Upholstery must be durable , easy to maintain, and most importantly, it must be fire retardant.

Fire retardant testing for the upholstery is another necessary procedure for class approval testing for the ferry seats.

Plastic components

The plastic components including beam ends and track ends. The main purpose of the plastic components is decoration and covering up the sharp corner of the aluminum beam and tracks. The material of the plastic components is ABS.The plastic components must be high strength.

Fastener

A lot fastener is used to assemble the ferry seats. It is extremely important in terms of the strength of the ferry seats and passengers safety. The fastener is including bolts ,nuts and washers. All items must be high quality stainless steel material.

Overall, the material used for ferry seats should be carefully selected based on factors such as strength, durability, and resistance to corrosion. By choosing high-quality materials for each component, ship owners can ensure that their ferry seats will provide a comfortable and safe experience for passengers during sea travel.

As a premier manufacturer of ferry seats for the past two decades, we are dedicated to delivering products of the highest quality. We extend a warm invitation to shipyards and ship owners worldwide to visit our factory and witness our commitment to excellence firsthand. We strive to collaborate with all our clients to achieve mutual growth and success.